Braking systems are vital to any vehicle, but a semi truck is perhaps the most critical type of vehicle when it comes to the importance of brakes. When 80,000 pounds of truck and trailer are barreling down the freeway, operators need to know that they will be able to stop efficiently and quickly when needed.

Brake failure is a common cause for accidents involving tractor trailers, and these accidents are an excellent cause for a lawsuit. If fleet owners wish to avoid a lawsuit, they should pay close attention to proper maintenance of truck brakes.

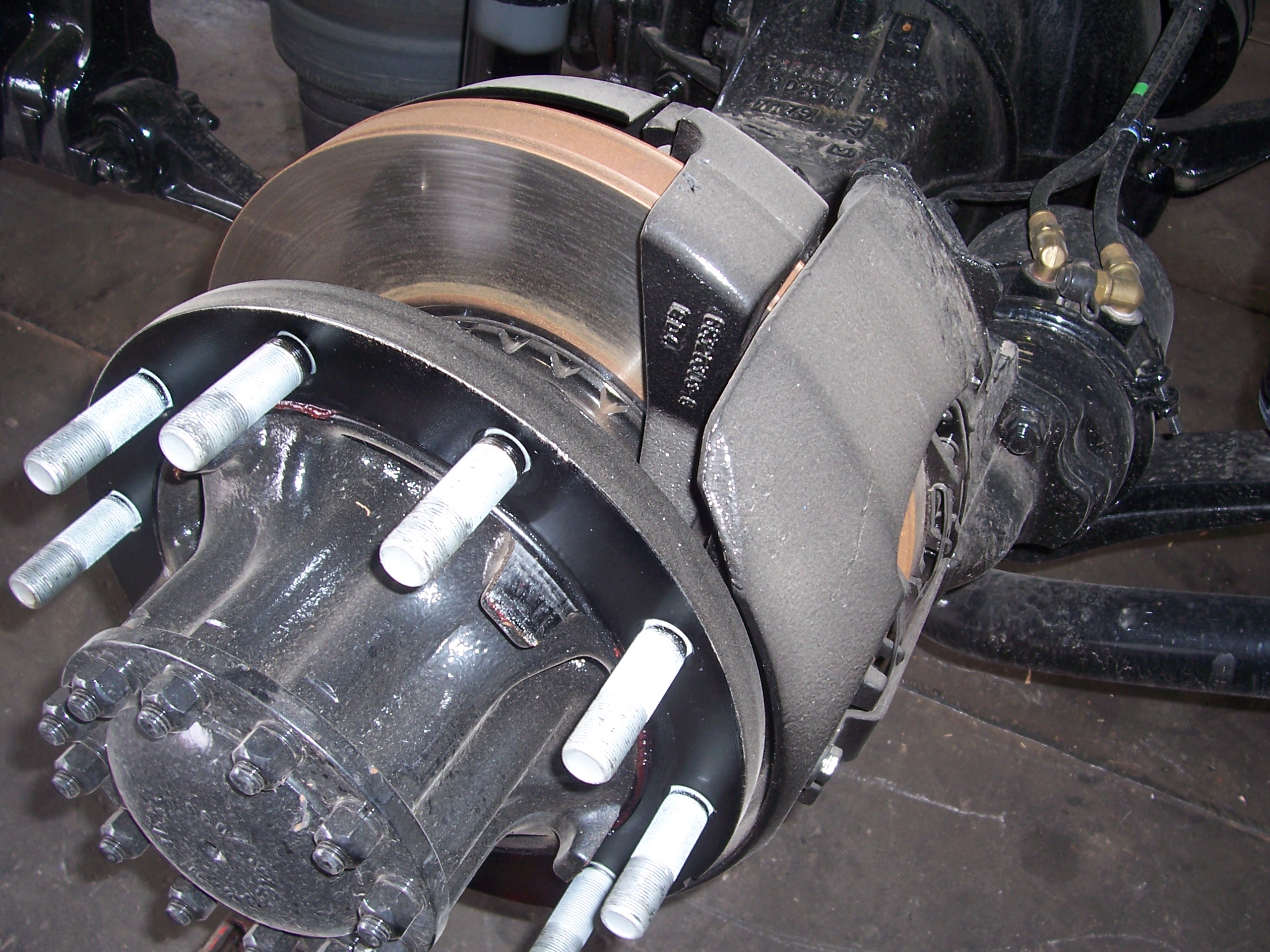

Air Disc Brake

Replace Pads and Other Parts

Brakes have parts that need to be replaced on a regular basis to keep them working well. Brake shoes have indicators built into the pads that show when replacement is necessary. When operators take their truck in to have the brake pads replaced, they should also replace the springs, pins and bushings for the brakes. The drums should also be replaced when the shoes are replaced, because they can wear down and can also develop heat cracks.

Grease the Slack Adjusters

The slack adjustors work to keep the brakes in alignment when they are used. Trucks can have either manual or automatic slack adjustors. Both need to be greased to work well.

Enjoying our insights?

Subscribe to our newsletter to keep up with the latest industry trends and developments.

Stay InformedAutomatic slack adjustors will automatically keep the brakes in adjustment, while manual systems require maintenance officials to do the adjustment themselves. Many operators forget about greasing the automatic slack adjusters, because they do not regularly use these. When the adjusters are not greased, they can seize up and stop working, which eventually leads to brake failure. When greasing slack adjustors, lithium grease is a good choice.

Check and Grease the S Cams

Slack adjustors work by turning a shaft that then turns the S cams. The S cams push the brake shoe into the drum to stop the truck. S cams are equipped with bushings. When brake shoes are changed, bushings should be checked as well. These may not need to be changed as frequently as the shoes, but they should be greased as part of your regular brake maintenance.

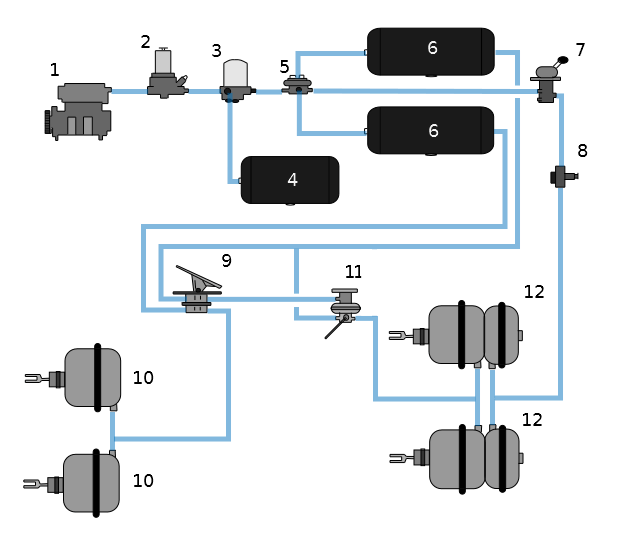

Air Brake System

Check the Air Compression Pressure Gauge

Application pressure is a crucial part of stopping a moving truck. Check to ensure that the gauge reads greater than 60 pounds per square inch (psi) before using the truck. Ideally, the pressure should run between 100 psi and 125 psi. If tires are consistently falling low on application pressure, the brakes should be serviced. If the pressure ever drops below 60 psi, the truck should not be used.

Check Linings and Hoses

Before using a truck, check all linings and hoses. Linings should not be soaked with lubricant and should be at least a quarter-inch thick. Air hoses must not have any cracks and should not appear worn. Proper brake maintenance requires replacing worn or damaged lining or hoses regularly.

When Should Brakes Be Serviced?

Finally, truck owners should set up a routine plan for having a professional service the brakes on semi trucks. While the distance a truck can travel between brake service is going to vary depending on the driving habits of the driver, it’s best to have the brakes inspected and maintained every time the truck’s oil is changed. This will keep the driver, the truck and everyone on the road with them as safe as possible.

(This article was originally posted at FleetAnwers.com)

Thanks for pointing out that it’s a good idea to have the truck’s brakes inspected and serviced every time the truck’s oil is changed. My brother recently purchased a used heavy duty truck to use for his construction projects. It’s a bit of an unconventional vehicle, so I want to make sure he does whatever he can to stay safe on the road. Next time I see him, I’ll definitely tell him to get the brakes inspected whenever he needs an oil change!