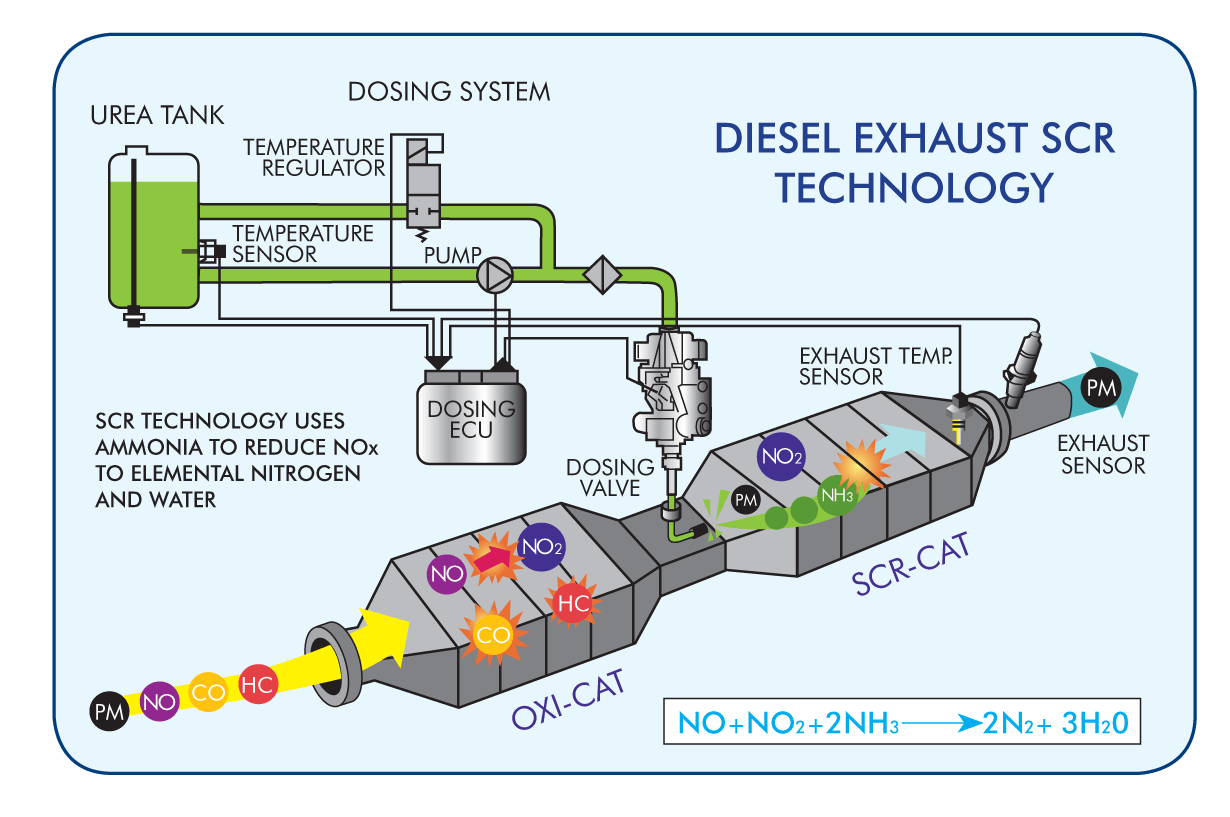

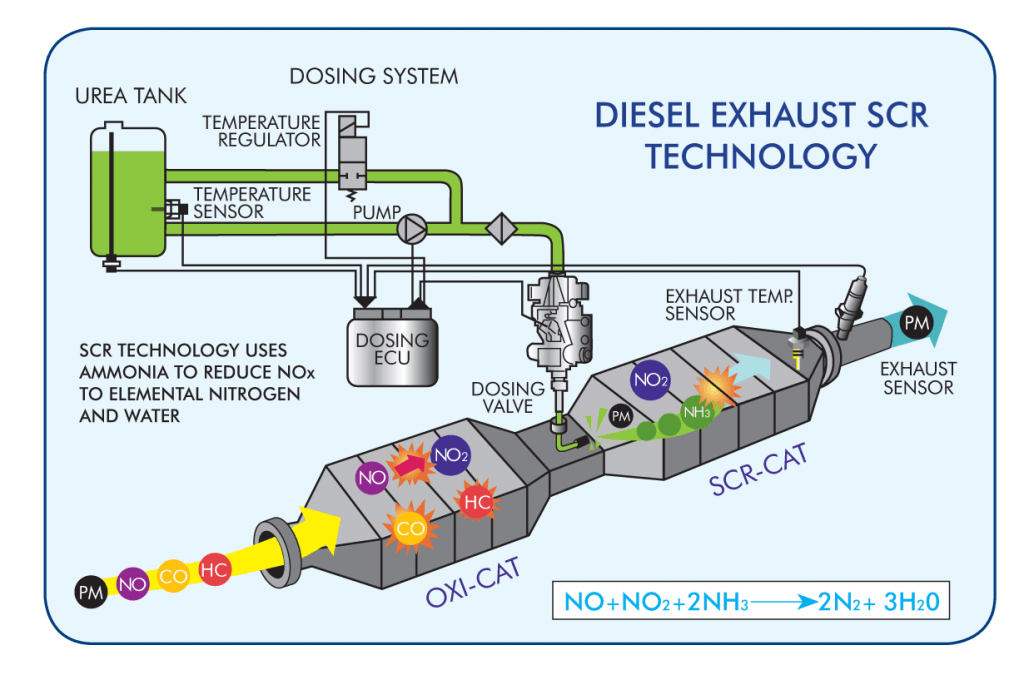

As the number of trucks equipped with selective catalytic reduction (SCR) technology continues to rise, fleet and maintenance managers are wondering how to make the most out of their diesel exhaust fluid (DEF), which is required to keep their vehicles running and compliant with the EPA’s Heavy Duty Engine and Vehicle Standards.

Luckily, there are a few simple steps that can be taken to ensure owners and operators are not over-spending on DEF, buying low-quality product, or ruining the DEF they’ve purchased.

Buy Based on Need

DEF is available in volumes ranging from small 2.5-gallon containers to 2,000-gallon mini bulk containers and beyond. As such, it’s important to determine the number of SCR-equipped vehicles in a fleet and the amount of DEF those vehicles consume per week.

For example, small fleets, with one to four vehicles and typically using 15 to 30 gallons of DEF per week, should try purchasing 55-gallon drums of DEF for the best savings.

Conversely, a manager overseeing five to nine SCR vehicles or a fleet consuming 60 to 90 gallons per week should consider purchasing DEF in 275 to 330-gallon intermediate bulk containers.

Enjoying our insights?

Subscribe to our newsletter to keep up with the latest industry trends and developments.

Stay InformedMoreover, fleets with 26 to 50 vehicles, or fleets using 300 to 600 gallons of DEF a week, ought to consider having DEF delivered in bulk. In this case, utilizing mini-bulk or other storage units with a DEF storage capacity of 2,000 or 3,000 gallons will help maximize cost efficiencies.

A fleet’s purchasing needs will likely change over time as the fleet continues to replace older vehicles with new SCR-equipped trucks.

As a fleet grows, working with a DEF specialist can help a fleet make the move to bulk as seamless as possible, with affordable and innovative equipment solutions.

Choose Quality

Another simple but often overlooked method of getting the most out of DEF purchases is to make sure quality DEF is being purchased. DEF is a product that needs to be in its purest form to protect an engines’ catalysts.

Therefore, it’s important to use only ISO 22241-certified DEF, not just any urea solution. Even small amounts of impurities in DEF may progressively damage an engine’s dosing and catalyst systems.

Worse yet, certain contaminants may cause catalyst deactivation, which may have a negative impact on an engine’s performance.

Ensure Reliability

In addition, with the U.S. DEF market expected to increase 30-fold by 2015, according to market research firm Integer Research, many fleet operators can be concerned about running out of DEF. This can put a damper on a fleet’s ability to operate, not to mention impact its bottom line.

Fleet managers should make sure they have a DEF supplier who can supplement domestic production with international production. The U.S. is an import market for urea, the base for DEF production, so a supplier with a strong import platform will be better positioned to ensure managers don’t experience a shortage as a result of a natural disaster or local demand spike.

Further, using a fuel and lubricant distributor in the U.S. who has a vast delivery network will also help ensure DEF is received when and where it is needed.

Educate your Team

Based on what is happening in Europe, we know that 80 percent of contamination happens at fleet terminals.

To safeguard against DEF contamination at the terminal, which can lead to vehicle downtime, managers should make sure everyone who uses or handles DEF follows these seven guidelines:

- Keep DEF away from materials such as fuel, oil, grease, water, dust, dirt, metal and detergent, as these items will contaminate DEF.

- If the DEF fueling equipment at the terminal needs to be cleaned, rinse it with de-mineralized water — not tap water.

- Only use dedicated DEF equipment for storing and dispensing DEF. Do not use funnels or bottles that have been used for other fluids.

- While a DEF pump’s magnetic guard will prevent workers from accidentally putting DEF into the wrong tank, be sure to insert the DEF nozzle into the truck’s DEF inlet to avoid contaminating the spout.

- Store DEF below 86 degrees (F) to maintain its optimal shelf life.

- Do not store DEF in direct sunlight.

- Do not refill previously used DEF containers, as they may be contaminated.

Keep Drivers in the Loop

It’s also important for drivers to know how long DEF will last them and where they can find it if they start to run low. On average, 2.5 gallons of DEF yields about 350 miles. That means, as a rule of thumb, drivers should refill their DEF tank every third time they fill their diesel tank.

In addition to using on-board GPS navigation systems to find the nearest DEF retailer while out on the road, some DEF manufacturers have made smart phone apps that can identify the DEF retail outlet closest to a driver’s location.

These apps can be very helpful as they allow users to search for DEF retailers by city, state and zip code, view a map with the various DEF refueling locations along their route and find the addresses of nearby DEF retailers.

Although these tips and guidelines for getting the most out of DEF aren’t widely known, adhering to them isn’t difficult. By purchasing the right amount of DEF, ordering it from a reliable supplier and educating colleagues about handling, storing, using and finding DEF, users will be able to maximize their fleet’s fuel and cost savings.