Digitization streamlines hazmat transportation for global chemical companies

Digitization streamlines hazmat transportation for global chemical companies. With the increase in production comes the demand for quicker and safer transporting of the raw materials or finished goods to end-users.

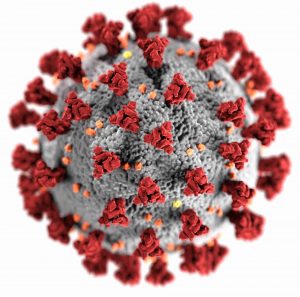

The world is a different place today than it was at the beginning of 2020, mainly because of the coronavirus that have led to big changes in the economy, socializing and executing business.

Global chemical companies are helping to fight the virus by stepping up production of hand sanitizers, polymers for personal protective equipment, bleach for disinfectants, and cleaning products.

Polyvinyl chloride, used to make construction pipes and vinyl siding, is now incorporated into medical tubing and IV bags. Polypropylene, used vehicle plastics, is now made into medical-grade personal protective equipment like masks and goggles. And over-the-counter and prescription medications contain numerous chemicals – many of these medicines are used to treat COVID-19 patients.

Quicker & Safer Transport

With the increase in production comes the demand for quicker and safer transporting of the raw materials or finished goods to end-users. This requires trucking firms to ship and transport chemicals safely to protect the environment and mankind. These companies need to step up their digitization efforts to speed processing. By eliminating spreadsheets and paper, companies can quicken workflows, boost productivity, reduce errors, and enhances compliance.

In transportation operations, a digital supply network acts as a technology platform for inter-business processes and supply chain relationships. It connects suppliers, buyers, shippers, and third-party logistics providers, allowing them to better communicate, collaborate and conduct business with each other. Manual processes like submitting a purchase order, acknowledging order acceptance, and shipment confirmation are automated, with paper or email translated to appropriate formats where the document can be shared with others electronically.

Enjoying our insights?

Subscribe to our newsletter to keep up with the latest industry trends and developments.

Stay Informed

The digital supply network brings visibility into carrier availability, helping logistics operators plan and optimize truck and carrier capacity.

Visibility into carrier availability

The digital supply network brings visibility into carrier availability, helping logistics operators plan and optimize truck and carrier capacity. Logistics posts the need for a load, and the carriers attached to the network can respond with their available assets, pricing per lane, and driver availability. Carriers can respond that they have the right credentials to handle hazardous shipments and loads can be scheduled.

The transport of hazardous materials is challenged with complex regulations that constantly change. These regulations require many companies to track and trace products from raw materials to the end customer. To meet rigorous compliance regulations and operate at peak efficiency, businesses need complete visibility for real-time traceability of products across the extended supply chain.

Transporters of dangerous goods need to use technology that provides visibility into shipments while in transit so that shippers will know where their products are at all times. Having visibility of orders across channels, partners, regions and systems and across the entire life cycle of the order from entry through proof-of-delivery helps to ensure that the shipment is safe and being transported correctly. Alerts can be created if an issue in the shipment arises and customers can be informed. Having visibility of a shipment in transit can alert customers in real-time to where their orders are at all times.

Documentation and Packaging

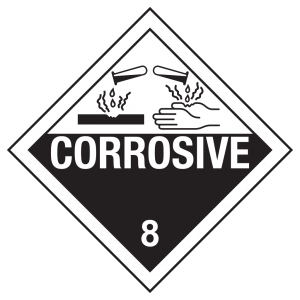

Hazardous materials shipments must be accompanied by clear documentation that includes the bill of lading, hazardous waste manifests, and a description of the material being transported. This description consists of the weight and quantity of the materials along with a description of the packaging.

Hazardous materials shipments must be accompanied by clear documentation that includes the bill of lading, hazardous waste manifests, and a description of the material being transported.

Shipments of dangerous goods must include emergency response information on the shipping document. This information details procedures that need to happen should an incident occur. Description of how to prevent fires and what to do in case of a leak are often included on this documentation.

A digital supply network fosters complete record-keeping because without proper records and documentation, companies can be found non-compliant with hazardous shipments, leading to great financial risk.

During these trying times, it is crucial that chemicals and hazardous materials are shipped in the correct packaging and handled by workers in protective gear, which includes safety glasses and impermeable gloves. According to UPS, hazardous materials must be packaged in multi-layer packaging that “consists of inner receptacles, cushioning and absorbent materials, and an outer packaging that has been designed, manufactured, tested and certified for the containment of specific hazardous material classes and packing groups.”

Infectious concerns

One of today’s big concerns in handling hazardous materials centers on the shipping of COVID-19 test samples. Existing medical evidence suggests that the coronavirus can live on certain packaging materials – for a day on cardboard boxes and three days on plastic. Therefore, manufacturers need to train workers for handling these packages, along with providing the workers with the right protective gear.

One of today’s big concerns in handling hazardous materials centers on the shipping of COVID-19 test samples.

These infectious-type substances are classified as Dangerous Goods and therefore certain packaging and shipping regulations must be strictly followed. Private or contract carriers must follow certain requirements for shipping these goods, such as making sure the test samples are shipped frozen. If samples are shipped via standard carriers like UPS, shipping requirements are stricter, and workers must be trained specifically to handle these shipments.

Shipping hazardous materials, whether infectious substances or highly flammable chemicals, requires special care and handling within manufacturing, packaging, and transportation operations. To ensure safety and compliance, visibility should extend from end-to-end across the supply chains of all parties involved, including carriers, shippers, manufacturers, and raw material suppliers.

Connecting to a digital network, automating processes across the network, and gathering information from transactions conducted across the network ensures that hazardous materials will be transported as safely and securely as possible. Plus, the information that is collected across the network can be shared, analyzed and measured for performance and continuous improvement initiatives.