- Tank Summit 2025 revealed seven breakthrough tanker safety innovations—from SafeHeat electric cargo‑heating to AI‑driven smart trailers—set to reshape fleet operations.

- Washington wins: streamlined hazmat credentials and a proposed dry‑bulk axle variance show fresh regulatory momentum for the tank truck industry.

- Go inside Kraft’s new 56,000-sq-ft La Porte hub to see how a 10‑bay service mega‑center and $1 M parts inventory are redefining tank trailer maintenance strategies.

Tank Summit 2025 Unveils 7 Groundbreaking Innovations in Tanker Safety

Kraft’s New Texas Facility Sets Stage for Tank Summit 2025

Kraft’s 56,000‑sq‑ft La Porte hub showcased during Tank Summit 2025.

The 2025 Tank Summit convened at Kraft Tank Corporation’s newly opened La Porte, Texas, facility, bringing together fleet executives, equipment suppliers, and industry experts to explore the latest in tank truck technology and safety. This second annual Tank Summit 2025 event – co-hosted by Kraft and Drōv Technologies – attracted about 80 industry leaders from tanker fleets across the country.

Held at Kraft’s 10-bay service mega-facility just south of Houston, the summit provided a venue for sharing expertise on tank trailer innovations and discussing emerging trends in the tank truck industry. Attendees toured the expansive 56,000-square-foot La Porte center – a new hub situated on 9 acres in the heart of the Gulf Coast petrochemical corridor – as Kraft showcased its state-of-the-art maintenance bays and extensive parts inventory.

Katherine Williams, Kraft’s marketing specialist, noted that the company helped sponsor and host the summit to share its own technological processes and safety innovations with peers, while also showcasing the new facility’s capabilities. The La Porte center, which opened for parts sales and service in late 2024, houses over $1 million in tank trailer parts (with a goal of $1.75 million by next year) in a 10,000-square-foot warehouse. It stocks a vast array of blowers, pumps, hoses, valves, gaskets, lighting, axles, suspensions, and other components to support chemical, crude oil, dry bulk, and petroleum haulers.

This breadth of inventory – sourced from major suppliers like Betts, Dixon, Gardner Denver, SAF-Holland, and others – ensures visiting fleets have a firsthand look at the resources available to keep tankers on the road. By hosting Tank Summit 2025, Kraft aimed to underscore its commitment to helping the tank truck community operate more safely and efficiently, aligning with the event’s focus on tanker safety innovations and collaborative problem-solving.

For more news and updates on Kraft Tank’s latest expansions and initiatives, check out our Kraft Tank news section.

Enjoying our insights?

Subscribe to our newsletter to keep up with the latest industry trends and developments.

Stay Informed

Industry leaders share safety innovations at Tank Summit 2025.

The summit’s opening remarks emphasized industry collaboration. “It’s a unique opportunity for all of us to connect, share ideas, and dive into some of the most important issues our industry is facing,” said Brian Pursley, Kraft’s director of sales. With support from co-host Drōv and sponsors like SAF-Holland/Haldex, ConMet, and Drōv Technologies, the agenda featured a mix of keynote insights and live demonstrations. Representatives from Dixon Valve & Coupling, PT Coupling, and Pilot Company were on hand to spotlight novel products and services, encouraging a hands-on look at new tanker solutions.

Throughout the day, participants engaged in Q&A sessions, equipment walk-arounds, and networking, leveraging the La Porte facility’s ample space for both educational seminars and interactive showcases. By design, the Tank Summit 2025 fostered an impartial, knowledge-sharing atmosphere – not a sales pitch environment – where fleet managers and suppliers could candidly discuss what is and isn’t working in the field and brainstorm safer, more innovative ways forward. The positive, collaborative tone was set early and carried through the summit’s conclusion, including an evening networking reception on the nearby Houston Ship Channel waterfront.

Washington Regulatory & Safety Highlights Drive the Agenda

NTTC’s Will Lusk discusses policy reforms affecting hazmat fleets.

A keynote address by Will Lusk, Director of Education and Government Relations at the National Tank Truck Carriers (NTTC), anchored the summit’s focus on regulatory updates and industry trends. Lusk delivered an impartial overview of the latest developments in Washington, D.C., illuminating how recent legislative actions and safety initiatives are poised to impact tank truck operations. Despite the partisan gridlock often associated with “the swamp,” Lusk struck an encouraging tone about progress being made on issues critical to tanker fleets.

For example, he highlighted a new federal law – long advocated by NTTC – that eliminates duplicative security background checks for hazmat drivers. The Transportation Security Screening Modernization Act (signed into law at the end of 2024) streamlines the credentialing process by consolidating the hazardous materials endorsement check with the Transportation Worker Identification Credential (TWIC) screening. Lusk explained that this common-sense reform will save drivers time and money while maintaining security, a significant victory that demonstrates the strength of the industry’s collective advocacy.

Another legislative priority on the horizon is addressing weight limits for dry bulk carriers. Lusk described reenergized efforts to secure a “dry bulk axle variance”, which would allow slightly higher axle weights for bulk loads that naturally shift during transit. In June 2025, bipartisan legislation known as the VARIANCE Act was introduced in Congress to permit a 10% axle weight variance for trucks hauling dry bulk commodities, without raising the 80,000-pound gross weight limit.

This change, strongly supported by NTTC, aims to let bulk haulers legally maximize loads and reduce the need to “underload” trailers due to weight distribution issues. Lusk noted that such a measure would improve efficiency for carriers transporting products like sand, cement, grain, and chemicals, boosting payloads while maintaining safety – truly a win-win for the industry if enacted.

On the safety initiatives front, Lusk discussed how NTTC is championing practical solutions to ongoing challenges. One example is the push to allow pulsating brake lights on trailers to reduce rear-end collisions. Many tank fleets and law enforcement agencies support the use of flashing or pulsing rear brake lamps as an attention-getting safety measure. Lusk explained that NTTC has been gathering data showing significant reductions in crashes when trailers use pulsating brake lights.

A 10 % axle‑weight variance for dry bulk haulers is gaining traction in Congress.

Given the promising results, NTTC is petitioning regulators for an extension of its current Federal Motor Carrier Safety Administration (FMCSA) exemption and, ultimately, a permanent rule change to permit these pulsating lamps broadly. “If it’s saving lives and we have the data to prove it, why not make it a rule and even the playing field?” Lusk posed. This proactive approach exemplifies how the tank truck sector is seeking regulatory flexibility to implement proven safety enhancements.

Lusk also touched on the advent of electric trucks and the unique hazards they may pose when combined with tanker operations. He noted concerns about the “potentially deadly combination” of high-voltage EV batteries and tank trailers hauling hazardous materials. NTTC is urging regulators to consider these factors as electrification advances, ensuring that safety standards evolve to address new risks.

Overall, Lusk’s address provided a positive yet realistic assessment. While Washington can seem dysfunctional, he insisted, “it’s not as bad as it seems,” and recent wins show that Congress is listening to the trucking industry’s needs. With ongoing advocacy on issues like fuel tax repeal, infrastructure investment, and technology adoption, Lusk expressed optimism: “The future is bright for our industry. It really is.”. His remarks underscored that policy progress and safety innovation must go hand-in-hand to secure a thriving, safer future for tank truck carriers.

For additional insights into NTTC’s regulatory efforts and industry advocacy, explore our NTTC news page.

🗓️ Regulatory Fast‑Track Timeline (2024‑2026)

| Date | Milestone | Next Action / Target |

|---|---|---|

| Dec 23, 2024 | Transportation Security Screening Modernization Act signed (Public Law 118‑202)—mandates unified TWIC/Hazmat background check. (Congress.gov) | TSA must publish a streamlined process by Dec 23 , 2026 (2-year statutory deadline). (Congress.gov) |

| Jan 17, 2025 | FMCSA notice on renewal of pulsating brake‑light exemption (Grote) opens 30‑day comment period. (FMCSA) | Decision expected Q3 2025; NTTC plans rulemaking petition immediately after. |

| May 05, 2025 | VARIANCE Act (H.R. 2920) introduced—10 % axle‑weight variance for dry‑bulk CMVs. (Congress.gov) | House T&I Subcommittee hearings slated for Fall 2025; companion Senate bill S.2108 pending. |

| Q4 2025 | Grote exemption expires (Dec 02 2025); FMCSA must issue renewal, or fleets revert to steady brake lamps. (FMCSA) | If renewed, the exemption runs ‑2029; otherwise, fleets must deactivate pulsing lights. |

| Dec 23, 2026 | Deadline for TSA to deploy consolidated credentialing portal & fee schedule per PL 118‑202. | Carriers update hiring SOPs; expect one‑stop TWIC/Hazmat renewal process. |

Pioneering Tanker Equipment Innovations at Tank Summit 2025

While big-picture policy and safety culture set the tone, Tank Summit 2025 was equally about hands-on technology demonstrations. A series of quick-hit presentations by leading suppliers highlighted game-changing tanker equipment innovations – many unveiled or showcased at the event – that promise to enhance safety and efficiency in bulk transport operations. SAF-Holland, together with its Haldex division, reviewed advanced components designed to improve tank trailer performance, including a super-duty air treatment system, smart brake systems, and an ultralight suspension. For instance, SAF-Holland introduced attendees to the new ApolloSDx™ air dryer, a five-stage filtration system engineered to deliver immaculate, dry air for brakes even in the harshest conditions.

ApolloSDx air dryer targets cleaner air for tanker brake systems.

They also showcased continuous brake pad wear sensors integrated into trailer disc brake calipers, which provide real-time brake lining status to simplify maintenance. Another innovation was the LifeSeal+ brake chamber, a 100% sealed spring brake chamber to keep contaminants out, and the CBX23 AeroBeam suspension, a remarkably lightweight 23,000-lb air suspension tailored for tank trailers. Coupled with ConMet’s Preset Plus® hub system – an integrated hub and spindle nut assembly that maintains clamp load and eases wheel-end service – these solutions target reliability and weight-savings, critical factors for tanker fleets. The SAF-Holland team’s message was clear: incremental engineering improvements, from stronger air dryers to lighter suspensions, can add up to meaningful gains in safety and payload capacity for carriers.

Other suppliers homed in on specific tanker operation challenges. Dixon Valve & Coupling (through its Bayco division) teased the next generation of overfill prevention systems for petroleum trailers, while PT Coupling introduced cutting-edge fluid handling equipment. These pioneering solutions, though varied in function, shared a common goal: eliminating risks like spills, product loss, and accidents during transport. Each presenter at the summit offered an impartial, facts-driven look at how technology can solve longstanding pain points in bulk transport. Below, we delve into two significant areas of innovation unveiled at the summit – one aimed at thermal control and fluid transfer, and another at spill prevention and smart trailer management – to understand how they promise to make tankers safer and more efficient.

SafeHeat System and High-Speed Pumping Unveiled by PT Coupling

One of the most buzzed-about developments at Tank Summit 2025 was the debut of PT Coupling’s “SafeHeat TTS” in-transit heating system, along with a new high-velocity pumping solution for tank trailers. Dave Palmer, PT’s transportation products market manager (holder of 27 tank-truck safety patents), introduced these innovations as breakthroughs poised to transform liquid tanker operations. What is the SafeHeat system, and how does it enhance tanker operations?

SafeHeat TTS is a self-contained electric heating unit designed to keep temperature-sensitive liquids – such as chemicals, waxes, food products like chocolate, or crude oil – at proper temperature inside a DOT407 insulated tanker without tapping into the tractor’s coolant. Traditionally, fleets have had to circulate engine-heated antifreeze from the truck through trailer plumbing to maintain product temperature. This inefficient practice can cause coolant cross-contamination between different tractors and even damage modern emission systems. Palmer lamented that this risky workaround, which often forces drivers to refill coolant while perched on a tire by the roadside, has been “industry-accepted” for lack of a better solution.

SafeHeat changes the game by using the truck’s 12-volt alternator power to run an onboard inverter and heating element, warming an isolated coolant circuit dedicated to the trailer. In simpler terms, it’s like giving the trailer its own built-in “electric boiler.” The corrosion-resistant system uses its antifreeze reservoir and a heat exchanger, preserving heat without drawing from the engine. SafeHeat’s compact module easily mounts on the back of the tractor’s cab (in the hose rack U-bolts) in about four hours, requiring no custom fabrication.

During the summit, PT Coupling demonstrated how SafeHeat maintains product temperature automatically and safely. The unit on display featured a TankTronics control module enabling remote monitoring of product temperature and system status. Operators can ensure that perishable or viscous cargo stays within target ranges throughout transit – preventing costly issues like solidification or spoilage – all while the truck’s primary cooling system remains untouched. According to Palmer, SafeHeat will prevent drivers from ever having to climb and pour antifreeze on the side of a highway, enhancing both safety and uptime. Early results are promising: field tests on two fleet tankers (running for 18–24 months) have delivered “perfect results,” Palmer noted.

Given that success, PT is gearing up to build 10 more units for additional fleet trials, cautiously ramping up production only once customers validate that “this is everything you said it was.” By inviting fleets to partner in these trials, PT aims to ensure SafeHeat meets real-world needs before a full rollout. If broadly adopted, this innovative heating solution could become a new industry standard for maintaining payload temperature efficiently, especially in cold climates or for products that must not cool down.

In tandem with SafeHeat, PT Coupling showcased a high-speed pumping system engineered for faster, safer unloading of liquid cargo. This reversible pumping solution allows refined fuels or crude oil to be unloaded (and even loaded) at unprecedented flow rates with zero product retention between jobs – meaning no leftover fluid is trapped in the lines after delivery. Palmer highlighted that the system can move crude oil at up to 512 gallons per minute, dramatically reducing loading/unloading times.

One major fleet partner, Energy Transfer, corroborated these gains: senior fleet manager Phillip McCracken reported that using PT’s pumping innovations cut their loading times by 30% and even improved fuel mileage by 2 MPG (by minimizing PTO idling time and optimizing transfers). The pump’s ability to completely evacuate product and reverse flow means drivers don’t have to worry about residual hazardous liquid remaining in hoses – a significant safety and environmental plus. Together, SafeHeat and the high-velocity pump tackle different challenges (thermal maintenance and transfer speed), but both contribute to a common outcome: safer, more efficient fluid handling for tank trucks. Palmer’s presentation resonated, as many fleet attendees saw immediate practical applications for these technologies in their operations.

To explore more news on PT Coupling and its tanker innovations, visit this page.

Smart Overfill Prevention and Trailer Telematics Boost Safety

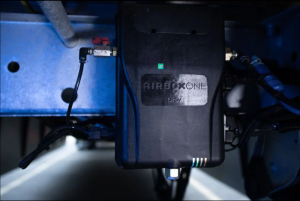

Drōv’s AirBoxOne forms the brain of Tank AI smart‑trailer systems.

Another core focus at the summit was leveraging smart technology to prevent incidents and optimize fleet performance. Dixon Bayco’s J.C. Dollinger took the stage to discuss next-generation overfill prevention. At the same time, Drōv Technologies’ Bob Davis (joined by Pilot Company’s Brent Hickman) demonstrated the latest in innovative trailer telematics. These systems address different aspects of tanker safety – one at the loading rack, the other on the road –. Yet, both rely on sensors, automation, and data integration to make tank truck operations safer and more intelligent. What new safety features were highlighted at Tank Summit 2025 in overfill systems and trailer monitoring?

Overfill prevention is a critical safety system on fuel and chemical trailers that stops product flow before a tank compartment overfills, preventing spills and fire hazards. Dollinger revealed that Dixon, a 109-year-old manufacturer, is collaborating with tech partners like Drōv to develop “smart” overfill systems with capabilities well beyond today’s optic sensors. The future overfill protection platform Dixon is testing will incorporate telematics, self-diagnostics, and remote sensors to detect issues in real time. For example, fleets would be alerted to faulty probe sensors before arriving at the loading terminal, avoiding loading delays or unsafe bypassing. The system will also measure temperature and volume in each compartment to a finer degree.

This helps track retention (liquid remaining) after unloading more accurately, and accounts for thermal expansion or contraction of product (since temperature affects liquid volume and weight). Such data could warn a driver if a compartment isn’t entirely empty or if product stratification has occurred. Additionally, Dollinger said Dixon’s design aims to identify different fuel types in each compartment to prevent accidental cross-loading (e.g., putting diesel in a gasoline tank). Currently, they can electronically distinguish diesel vs. gasoline; eventually, the goal is even differentiating grades of gasoline – a sophisticated task but within reach.

The upcoming system will likely integrate anti-theft and security features as well: using sensors and geofencing, it could trigger alarms or even lock out a compartment if an unauthorized unloading is attempted outside designated areas. All told, Dixon’s brilliant overfill initiative seeks to provide predictive maintenance and enhanced security for cargo tanks, reducing both spills and theft. One fleet representative at the summit expressed keen interest – “We may end up running a pilot with Dixon’s overfill system,” said Energy Transfer’s Phillip McCracken, impressed by the potential to catch problems proactively. By connecting loading rack equipment to the broader telematics ecosystem, these advancements could significantly improve safety and operational uptime for fuel haulers.

For additional insights into overfill prevention technologies and safety protocols, explore our coverage on overfill prevention.

Meanwhile, Drōv Technologies showcased how smart trailer systems can optimize operations on the road. Davis introduced Tank AI – a comprehensive intelligent trailer platform powered by Drōv’s flagship product, the AirBoxOne™ control unit. This system unifies a host of sensors and automation into a single interface, turning a conventional tank trailer into a “smart trailer”. Pilot Company’s Brent Hickman joined to share real-world results, since Pilot has been testing AirBoxOne on its fuel tanker fleet for a couple of years.

The system integrates ABS brake monitoring, tire pressure and temperature sensors, hub vibration sensors, axle weight gauges, and even cargo camera feeds, all onto one screen. By aggregating data that was previously siloed across many separate devices, Tank AI gives fleets holistic visibility into each trailer’s health and status in real time.

One standout feature is dynamic tire inflation/deflation controlled by the intelligent system. As Hickman explained, Drōv’s AirBoxOne can automatically adjust trailer tire pressures based on the load weight and road conditions – inflating or deflating on the fly to maintain optimal tire footprint. This not only improves safety (reducing blowout risk) but also significantly extends tire tread life. Pilot’s data showed over 50% longer tire life on test trailers, equating to savings of more than $1,000 per trailer annually.

Additionally, by precisely monitoring axle weights, the system helps ensure each load is optimized. Hickman gave a concrete example: squeezing just an extra 50 gallons of payload into a fuel trailer (when safe and legal to do so) across 1,250 loads per year yields about 62,500 additional gallons transported, roughly eight extra loads, which for Pilot means about $3,125 in extra revenue per trailer per year (at $0.05 per gallon freight rate).

In essence, smart load management directly boosts the bottom line. Importantly, the platform also monitors critical safety metrics – if a wheel-end starts to overheat (a precursor to bearing failure or fires), the system alerts the driver and dispatch, potentially preventing catastrophic “hot wheel” incidents. Drōv announced at the summit a new integration with SKF’s TraX wheel-end sensors to enhance this capability.

Hickman noted that the biggest challenge today is not a lack of data. Still, rather than the integration of data streams, fleets are juggling multiple apps and dashboards for tires, brakes, telematics, cameras, etc.. Tank AI’s value is in consolidating all trailer data into one user-friendly system. This reduces driver distraction and ensures nothing slips through the cracks. Pilot’s experience demonstrates that such smart trailer tech can yield tangible improvements in safety, maintenance, and profitability. As more fleets and trailer OEMs (like EnTrans, maker of Heil and Polar tanks) adopt Drōv’s platform, we can expect smart trailers to become increasingly common in the hazardous materials transportation arena.

The Tank Summit audience – including maintenance directors from tanker fleets – showed strong interest in these developments, recognizing that better asset intelligence can translate to fewer roadside emergencies and more efficient deliveries. The consensus from these tech showcases was clear: whether it’s preventing an overflow at the rack or detecting a failing wheel bearing before it causes a fire, integrated smart systems are ushering in a new era of proactive safety for tank trucks.

For more news and updates on Drōv Technologies and its innovative trailer systems, check out this page.

📊 ROI & Implementation Snapshots

1. Drōv Tank AI / AirBoxOne Smart‑Trailer Platform

- Investment: Lane‑3 package ≈ $3,900 per trailer.

- Payback: < 2 months; annual return ≈ $25,000 per trailer (EnTrans analysis of Pilot tests). (Drōv Tank AI)

- Hard Metrics

- Tire life ↑ 54.4 % (14,893 → 32,649 mi per /32nd) = six fewer tire sets; ≈ $20,000 saved over 20‑yr life.

- Load revenue: dynamic inflation + weight sensors add 50 gal/load → 62,500 extra gal/yr (1,250 loads) ≈ $3,125 margin.

- Roll‑out Steps

- Spec Lane‑3 on new builds or retrofit kit.

- Integrate via a single AirBoxOne dashboard (includes ABS, hub, tire, weight, and temp).

- Review ROI after 60 days; scale fleetwide.

2. PT Coupling High‑Velocity Reversible Pump

- Performance: Crude transfer up to 512 gpm; Energy Transfer cut loading time by 30 % and gained +2 MPG during pump‑idle cycles. (PT Coupling)

- Cost‑Benefit (example): For a 100‑load/month crude fleet, 30 % faster cycle = 30 loads of driver/terminal time freed; 2 MPG over 15,000 mi saves ~750 gal diesel/year.

- Roll‑out Steps

- Swap existing PTO pump for PT unit; keep plumbing identical.

- Train drivers on the reversible unload procedure.

- Monitor fuel/mileage KPIs quarterly.

3. PT Coupling SafeHeat TTS In‑Transit Heating

- Field Proof: Two units running 24 mo/18 mo with zero failures; eliminates coolant cross‑contamination and roadside refills. (PT Coupling)

- Projected Gains (pre‑production): avoids engine‑coolant dilution (can void OEM emission warranties worth >$8k) and removes 30–60 min driver labor per refill.

- Roll‑out Steps

- Four‑hour bolt‑on behind the tractor cab.

- Fleet pilot (PT seeking 10 partners); data share back to PT.

- Approve bulk order after 6-month validation.

4. SAF‑Holland CBX23 AeroBeam + P89 SLT Disc Package

- Weight Savings: 124 lb per tandem (62 lb/axle). (SAF Holland)

- Revenue Impact (diesel example): frees ~18 gal payload; at $0.05 freight rate = $0.90/load → $1,100 per trailer annually (1,250 loads).

- Roll‑out Steps

- Specify CBX23 + P89 SLT on new tanker orders.

- Verify compatibility with wheel‑end telematics (SKF TraX, Drōv).

- Track payload increase in TMS.

What services does Kraft’s La Porte facility offer to tanker fleets?

Kraft Tank’s new La Porte facility not only served as a backdrop for the summit’s presentations, but is itself a major boon to tanker fleets in the region. Opened in late 2024, this full-service tanker center provides maintenance, repair, parts sales, and soon trailer sales/leasing all in one location. The 10-bay workshop is equipped to handle everything from routine tanker inspections and refurbishments to complex barrel repairs – with the company in the process of securing its R-Stamp certification for code tank alterations.

Kraft Tank’s La Porte hub champions safer, smarter tanker operations.

The facility’s massive parts warehouse (targeting $1.75 million in inventory) means that fleets can source a wide range of components on the spot, minimizing downtime. Items in stock span foreign and domestic tanker parts: pumps, blowers, valves, hoses, lighting, suspension kits, brake systems, and more, from trusted brands like Dixon, Civacon, Gardner Denver, Hendrickson, Truck-Lite, Timken, and others. By stocking such a breadth of parts, Kraft ensures that visiting tank-truck operators – whether hauling chemicals, petroleum, dry bulk, or food-grade liquids – can find the exact replacement components or upgrades they need.

Additionally, the La Porte location offers field services with two mobile service trucks ready to perform on-site repairs at customer yards or terminals. The shop itself boasts modern equipment like a Continental hydraulic hose crimper, high-capacity air compressors, and overhead cranes to handle tanker service jobs efficiently. The strategic location (neighbored by a tank wash and in the heart of the Houston petrochemical and refining cluster) makes it convenient for Gulf Coast fleets to utilize Kraft’s offerings. In the coming months, Kraft plans a formal grand opening and further expansion, including additional service bays and a large covered awning for outdoor work.

The company is also growing its team – aiming to hire up to 30 skilled mechanics – to meet anticipated demand from regional and national fleets. For tanker operators, having this regional super-center means quicker turnarounds for tank trailer maintenance and a trusted partner that understands the unique needs of tank equipment. As Spencer Kraft (CEO) and Jeff Creel (La Porte GM) have emphasized, the goal is to “change the game” in tanker service by offering an unprecedented level of support in the area.

The enthusiastic response from Tank Summit attendees touring the facility suggests Kraft is well on its way – many were struck by the “wow factor” of a service center of this scale dedicated to tank trucks. By investing in La Porte, Kraft Tank Corporation is not only expanding its business footprint (now up to four locations nationwide), but also bolstering the infrastructure that tanker fleets rely on to operate safely and efficiently.

How will the Tank Summit shape future tanker safety and operations?

As Tank Summit 2025 concluded, participants left with more than just business cards and branded brochures – they gained actionable insights and a sense of momentum in tackling the industry’s challenges. The event’s impartial, content-rich approach ensured that every attendee, from fleet maintenance managers to product engineers, took away something valuable. On the regulatory side, fleets are now better informed about upcoming rules and can prepare for changes like the new background check process and potential weight variances.

This translates to adjusting internal policies to take advantage of eased credentialing (making hiring easier) and spec’ing future trailers to benefit from any allowable weight flexibility. On the technology side, many carriers expressed interest in trialing the showcased innovations. Some are likely to become early adopters of systems like SafeHeat or Drōv’s innovative trailer platform, integrating those solutions into their tanker fleets to test the promised gains in safety and efficiency. Equipment suppliers, too, gained feedback – for example, Dixon’s overfill R&D will benefit from fleets volunteering for pilot projects, and PT Coupling will be aligning its production of SafeHeat units with the fleets who stepped up at the summit to participate in the next round of testing.

Perhaps most importantly, Tank Summit reinforced the value of communication and collaboration across the tank truck ecosystem. The open dialogue – whether about a persistent maintenance headache or a new regulatory hurdle – helps ensure that solutions are developed with real-world input. As Brian Pursley noted, partnerships between fleets and suppliers mean technology providers “believe in what \[fleets] stand for” and strive to help them run “safer, smarter, and more efficient operations.”

For more coverage on fleet safety initiatives and best practices, visit our Fleet Safety news archive.

The positive energy and exchange of ideas at the summit will likely carry over into daily operations, industry committee meetings, and next year’s event. In fact, with two successful summits now completed (the first in 2024 hosted by Drōv in Oklahoma, and this one by Kraft in Texas), there is growing enthusiasm to make it an annual tradition that rotates among industry hubs.

By spotlighting tanker safety innovations and fostering frank discussions, the Tank Summit is fast becoming a catalyst for continuous improvement in the bulk transport sector. As one might say, the tanker industry doesn’t compete on safety – it’s a shared mission.

To stay abreast of emerging developments in tank safety across the industry, check out our tank safety news page.

Events like Tank Summit 2025 underscore that sentiment, proving that when competitors come together to share knowledge, everyone wins – carriers, suppliers, and the public who count on hazardous materials being transported with the highest safety standards.

For more news spanning the broader transportation industry, explore our transportation news section.

Tank Summit 2025 – Key Developments

- Kraft Tank Corp. opened a 10‑bay, 556,000-sq-ft La Porte, TX super‑center with $1 M parts inventory, aiming for $1.75 M by 2026.

- PT Coupling debuted SafeHeat TTS electric in‑transit heating and a reversible 512 gpm pump that leaves zero product retention.

- Dixon Bayco previewed a telematics-enabled overfill-prevention system with real-time diagnostics and product identification.

- SAF‑Holland/Haldex launched the ApolloSDx air dryer, LifeSeal+ sealed brake chamber, and ultralight CBX23 AeroBeam suspension.

- Drōv Technologies’ Tank AI smart‑trailer platform—tested by Pilot Co.—delivers >50 % longer tire life and $3 000 extra revenue per trailer.

- NTTC secured hazmat-background-check consolidation into one credential and is championing a dry-bulk axle-weight variance and pulsating brake-light rulemaking.

Authoritative External Resources for Tank‑Summit Topics

- Learn more about Kraft Tank’s nationwide sales, leasing, and service network on the Kraft Tank Corporation website.

- Explore PT Coupling’s full catalog of fluid‑handling fittings and safety equipment via the PT Coupling corporate site.

- Review the features of the AirBoxOne™ smart‑trailer platform on the Drōv Technologies product page.

- See NTTC’s current legislative and regulatory priorities on the NTTC Strategic Priorities 2025 page.

- Read the complete Federal Register notice on the FMCSA pulsating brake‑light exemption renewal.

- Access Public Law 118‑202, the Transportation Security Screening Modernization Act of 2024.

- Track the progress of the dry‑bulk axle bill on the H.R. 2920 VARIANCE Act page.

- Get technical details on the new ApolloSDx™ air‑treatment system in SAF‑Holland’s official product release.

- Download specifications for Dixon’s FloTech® Checkmate FT151 sensor from the Dixon Valve overfill‑detection product page.

- Review TSA guidance on the Hazmat Endorsement Threat‑Assessment Program and TWIC reciprocity.