- HM-265 fuel compliance is more than a placard tweak—learn how the “lowest flash point” ID-number marking option can reduce daily swaps and what to show roadside when the ID number reflects the previous business day.

- The biggest pitfall isn’t UN1203—it’s >10% ethanol blends (UN3475/UN1987). See the decision logic that keeps your HMR markings aligned with Emergency Response Guidebook (ERG) expectations.

- Cargo tank shops receive quiet but meaningful upgrades: FMCSA electronic registration options and video/fiber-optic inspection allowances that can reduce confined-space exposure while preserving inspection rigor.

PHMSA’s HM‑265 changes markings workflows—but emergency response still starts with the basics: correct shipping papers and fast ERG access.

If you run fuel or hazmat operations, HM-265 fuel compliance is one of those “small wording, big workflow” rules: it changes what drivers can display on a cargo tank, how shops can register, what inspection tools are allowed, and how certain specialty operations (like chlorine) document pressure relief device compliance. The rule is published in the Federal Register and becomes mandatory on Feb. 13, 2026, with voluntary compliance allowed starting Jan. 14, 2026.

For most fuel carriers, the headline is simple: PHMSA restores a long-standing petroleum distillate marking practice that can eliminate a large chunk of daily placard/ID swapping—while still keeping guardrails for higher-ethanol blends that drive different fire-suppression considerations. (If you want a refresher on when placards apply in day-to-day operations, see this placarding guide.) At the same time, HM‑265 also modernizes cargo tank shop processes (electronic submission), expands inspection options (video/fiber-optic), updates reflectivity requirements for certain uninsulated tanks, and clarifies how chlorine PRDs are referenced through incorporation by reference.

HM-265 fuel compliance: what changes on Feb. 13, 2026

HM‑265 is a final rule issued by the Pipeline and Hazardous Materials Safety Administration under Docket PHMSA‑2018‑0080 (HM‑265), and it amends 49 CFR Parts 107, 171, 172, 173, 178, and 180. It is effective Feb. 13, 2026, with voluntary compliance beginning Jan. 14, 2026, and the rule’s incorporation-by-reference approvals also take effect Feb. 13, 2026. For teams that prefer a downloadable copy for offline review, the public inspection PDF version of the final rule is available.

From a practical “what will change in my day” standpoint, HM‑265 is best understood as a targeted bundle:

- Petroleum distillate identification-number marking flexibility (the big one): “lowest flash point” marking can be based on what was hauled in the current or previous business day (with critical carve-outs for >10% ethanol blends). (See 49 CFR §172.336.)

- A conforming fix to prohibited marking rules so that using the new petroleum distillate marking flexibility doesn’t automatically trigger “wrong product displayed” violations under the general prohibition. (See 49 CFR §172.303.)

- Cargo tank facility registration may be submitted electronically via FMCSA’s portal (paper submissions are still allowed).

- Chlorine cargo tank PRDs: incorporation by reference is updated to the full Pamphlet 49 (Edition 10, 2016), and the PRD reference is conformed accordingly.

- Hazmat employee training: expands a packaging-focused training exception and removes security awareness training for employees whose hazmat work is limited to specific packaging activities (and who do not offer/transport hazmat).

- Reflective design rules: allow external coverings other than paint (e.g., reflective wraps/coatings) so long as reflectivity requirements are met.

- Cargo tank inspection tools: permit video cameras or fiber-optics for tests and inspections/inspections where required areas/elements are to be viewed and evaluated. (See 49 CFR §180.407.)

HM‑265 is PHMSA’s signal to fuel fleets: reduce unnecessary churn, but keep the proof—and the exceptions—tight.

Enjoying our insights?

Subscribe to our newsletter to keep up with the latest industry trends and developments.

Stay InformedPHMSA estimates that the amendments collectively provide approximately $145.3 million in quantified annual cost savings. (PHMSA describes these savings as largely driven by petroleum distillate marking/placarding efficiencies.)

Implementing HM-265 fuel compliance by Feb. 13, 2026

Think of HM‑265 as a workflow change with compliance consequences. The fastest, cleanest implementations usually do two things in parallel:

- Rewrite the SOP in plain language (what the driver does, what dispatch confirms, what the shop installs/updates). For fleet-facing execution ideas, see transport fleets coverage.

- Build proof on demand (what you can show roadside in under a minute when an ID number reflects prior-day hauling). A practical documentation refresher is this hazardous material shipping guide.

To help you map your own rollout, HM‑265’s biggest operational impact lives in 49 CFR §172.336 (identification numbers; special provisions) and the conforming change in §172.303 (prohibited marking).

HM-265 fuel compliance: the petroleum distillate ID-number rule explained

What the rule allows (plain English): If your cargo tank transports more than one petroleum distillate fuel in different trips on the previous or current business day, you may display the identification number for the liquid petroleum distillate fuel having the lowest flash point transported in that previous/current business-day window.

PHMSA defines a “business day” as “a day that the operator of the cargo tank motor vehicle is open and operating in commerce.”

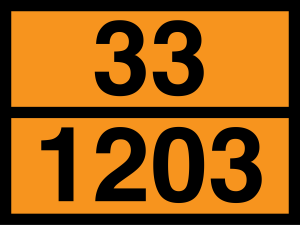

PHMSA also provides the practical example fleets care about: haul gasoline on Day 1, haul diesel only on Day 2, and you may still display “1203” on Day 2 because gasoline has a lower flash point than diesel.

Two details insiders should not gloss over:

- The regulatory text addresses two real-world scenarios inside the §172.336 table:

- Multiple compartments carrying different petroleum distillate fuels simultaneously (compartmented cargo tanks or tank cars).

- Different trips over the prior/current business day (the “I hauled X yesterday, Y today” pattern that drives the constant placard swaps).

- The HM‑265 approach is not framed as “ignore what’s in the tank.” It’s framed as: “for petroleum distillate fuels with similar initial response guidance, allow a controlled marking flexibility that’s easier to operationalize.” PHMSA ties that rationale to the Emergency Response Guidebook, pointing relevant petroleum distillate fuels to the same initial response guidance (Guide 128).

HM-265 fuel compliance and the “previous business day” workflow

If the ID number reflects a prior-day load under HM‑265, the roadside question is simple: Can your shipping papers and dispatch records support it?

Most fleets will either win or lose this rule at the handoff points: dispatch → driver, and driver → enforcement/first response documentation.

Here’s what a durable workflow usually includes—without overcomplicating the cab:

1) Dispatch/TMS decision rule (the “what do I display?” logic)

Build a simple hierarchy that mirrors §172.336 and avoids common traps:

- Step A: “Am I transporting a gasoline/alcohol blend with more than 10% ethanol?”

- If yes, you must display “3475” or “1987” as appropriate, and you may only display those when that material is present during transportation.

- Step B: If not, review petroleum distillate fuels transported on the current or previous business day, and select the product with the lowest flash point within that window; display its identification number.

2) Driver-facing “one sentence” instruction (keeps roadside interactions short)

For many operations, the most effective cab script is something like:

- “This ID number reflects the lowest-flash-point petroleum distillate we hauled today or the previous business day; shipping papers show what’s currently onboard.”

That is consistent with PHMSA’s expectation that shipping paper records can be used to determine whether a lower-flashpoint fuel was transported in the previous business day, and that transporters will have access to supporting information.

3) Proof on demand: what you want available within 60 seconds

HM‑265 doesn’t create a brand-new “recordkeeping requirement,” but it does create a predictable enforcement question: “What did you haul in the previous business day?” That’s why your fastest path is usually:

- Current shipping papers (what’s on board now)

- Prior business day load confirmation / BOL reference in the TMS (what was hauled in the relevant window)

- A quick internal lookup (terminal ticket, dispatch record, or electronic trip record)

PHMSA explicitly addresses enforcement concerns raised by the Kansas Highway Patrol regarding roadside inspection burdens and expects law enforcement to use shipping paper records and for transporters to have access to the necessary information.

4) The compliance “pressure test” scenario you should run internally

Before Feb. 13, run tabletop drills using scenarios that are known to confuse:

- Holiday weekend or multi-day layoff: what is the “previous business day” for your specific operator? PHMSA notes enforcement raised this exact scenario (the previous business day could be several days prior, depending on operations).

- Slip-seat operations. Does the driver know what was hauled on the previous business day if they’re picking up a tractor/trailer or a tank they didn’t operate yesterday? (Again, a cited enforcement concern.)

- Mixed fleet operations: how do you keep the ethanol rule from being “accidentally” applied to everything (or missed entirely)?

Can I keep UN1203 displayed if I’m hauling only diesel today?

Under HM‑265, yes—sometimes, and that “sometimes” is the point: if gasoline (UN1203) was the lowest-flash-point petroleum distillate transported in the current or previous business day, HM‑265 allows that marking to remain displayed even if today’s load is diesel only. PHMSA provides the following example: gasoline on Day 1, diesel only on Day 2, and “1203” may be displayed on Day 2.

The “not always” answer is driven by the >10% ethanol carve-out (next section).

What counts as the “previous business day” for fuel deliveries?

PHMSA defines “business day” in this context as a day on which the operator is open and engaged in commerce—not necessarily “yesterday” on the calendar. That matters for weekend/holiday/non-operating days, as well as for operations with irregular schedules.

Ethanol blends (>10%): the UN3475 / UN1987 trap you need to engineer out

HM‑265’s biggest ‘gotcha’ is ethanol content: higher-ethanol blends have tighter ID-number display rules than standard petroleum distillates.

HM‑265’s headline benefit comes with a high-value exception: gasoline/alcohol fuel blends consisting of more than 10% ethanol.

In the §172.336 table language, if a cargo tank contains gasoline and alcohol fuel blends consisting of more than 10% ethanol, the identification number “3475” or “1987,” as appropriate, must also be displayed. Those identification numbers may only be displayed if the material is present in the cargo tank during transportation.

PHMSA’s rationale is straightforward: high-ethanol blends may require different fire-suppression media. PHMSA notes that foams tailored for high-ethanol-content gasoline are available and excludes UN3475 from the broader marking exception.

Where fleets can stumble on compliance:

- Yesterday you hauled a >10% ethanol blend (so “3475”/“1987” becomes the lowest-flash-point item in the relevant window).

- Today, you haul straight diesel or another petroleum distillate without that high-ethanol blend.

- You keep displaying “3475” or “1987” out of habit, because it was “allowed” under the previous/current business day logic.

HM‑265 does not allow that: “3475”/“1987” may only be displayed if the material is present during transportation.

A fleet-proof way to implement this without driver guesswork

If you have a dispatch/TMS system, hard-code two rules:

- Rule 1 (ethanol override): If UN3475/UN1987 is on board now, display it now (as required).

- Rule 2 (ethanol removal): If UN3475/UN1987 is not on board now, do not display it—regardless of what was hauled yesterday.

Then the petroleum distillate “lowest flash point in previous/current business day” logic serves as the fallback only when you are dealing with petroleum distillate fuels other than high-ethanol blends.

Why is this also a roadside issue, not just a policy issue

Enforcement commentary highlighted potential conflicts with out-of-service criteria and general expectations that placards/IDs match what’s present. PHMSA responded by creating a conforming exception under §172.303(b)(4) for CTMVs marked in accordance with the petroleum distillate fuel marking requirements in §172.336.

That exception helps, but it won’t cover you if you incorrectly display UN3475/UN1987 when the material is not present, because HM‑265 explicitly restricts those to “present during transportation.”

The controversy you should expect readers to ask about

PHMSA received stakeholder concerns that emergency responders could be confused if markings don’t reflect the actual contents, including comments from the International Association of Fire Fighters and the International Association of Fire Chiefs. PHMSA’s response emphasizes that petroleum distillate fuels follow the same ERG guide for initial response (Guide 128), that shipping papers provide specifics, and that high-ethanol blends are excluded due to different fire-suppression considerations. (For teams that want the source document handy, here’s the ERG 2024 PDF.)

Other HM-265 changes that still hit your SOPs

The identification number is the signal—HM‑265 changes when certain numbers can stay displayed, not the importance of getting that signal right.

Even if you don’t haul petroleum distillates, HM‑265 has “quiet” changes that matter to cargo tank facilities, specialty commodities, and packaging operations. For many organizations, these are the provisions that will show up in audits or internal compliance reviews six months after Feb. 13—because they were easy to miss during the UN1203 conversation.

Below are the non-headline changes, translated into operational terms.

1) Cargo tank facility registration: electronic submission becomes an option (Part 107, Subpart F / §107.502)

PHMSA revises §107.502(d) so registrants may submit cargo tank facility registration information electronically via FMCSA’s portal (and still may submit a hard copy to FMCSA).

This is not just “paperwork modernization.” It changes what your compliance team should treat as the system of record:

- If you switch to electronic submission, align internal controls: who submits, who confirms acceptance, where confirmation receipts live, and what you can produce during an audit.

- If you stay paper-based, document why (e.g., policy choice, internal controls, or conservative preference) so it doesn’t look like an oversight.

PHMSA addresses a cybersecurity concern raised by a commenter, noting that FMCSA already stores large volumes of carrier/driver data with security measures in place and is not aware of any failures in those protections.

2) Chlorine cargo tanks: PRD references shift to full Pamphlet 49 incorporation

HM‑265 updates §171.7 to incorporate by reference Pamphlet 49, Recommended Practices for Handling Chlorine Bulk Highway Transports, Edition 10 (December 2016).

The rule also revises §173.315(i)(13) to require that a pressure relief device on a chlorine cargo tank conform to one of the drawings in Pamphlet 49 (IBR; see §171.7).

Critically, PHMSA explains that incorporating Pamphlet 49 in its entirety has the effect of authorizing an additional PRD design—specifically the Midland Type A‑14227‑ML PRD design for chlorine service.

What chlorine carriers and shops should do with that:

- Audit PRD documentation and maintenance records against the incorporated drawings.

- Align procurement specifications so the “IBR source” is the controlling reference (and your shop can reference it during inspections).

- If you operate across multiple terminals, ensure all facilities can consistently access the incorporated material; inconsistent access is a predictable weak point in compliance programs.

3) Hazmat employee training: packaging-only scope is narrowed (and clarified) under §172.704

PHMSA amends §172.704 so that certain employees whose hazmat work is limited to manufacturing/repair/modification/reconditioning/testing of packagings (and who do not perform any other HMR function) are not subject to the training requirements in paragraphs (a)(3) and (a)(4)—the provisions related to safety training and security awareness training. (Related: hazmat training and compliance basics.)

This is a compliance overhead reducer, but it’s also a “scope clarity” issue. In practice, you’ll want to document:

- Which roles are truly packaging-only under your job descriptions and workflow reality

- How do you prevent “role creep” (an employee who sometimes offers hazmat for transportation is no longer “packaging-only”)

- How training assignments change when the employee’s scope changes

4) Reflectivity on uninsulated tanks: not just paint anymore (§178.337‑1(d))

HM‑265 turns hazmat marking into a workflow question: what’s displayed matters—but what you can prove roadside matters more.

HM‑265 revises §178.337‑1(d) to allow uninsulated tanks to use external coverings other than paint—PHMSA specifically cites reflective vinyl wraps and other innovative reflective coatings—as long as reflectivity requirements are met.

The revised regulatory text preserves the reflectivity requirement: an uninsulated cargo tank must be a reflective color (white, aluminum, or similar) on the upper two-thirds of its surface unless covered with a jacket made of bright, non-tarnishing metal.

Practical implications for fleets and builders:

- Branding/appearance changes may be easier to execute without accidentally creating a compliance defect.

- Shops should maintain documentation of the materials used (wrap/coating specifications) and ensure the finished tank meets the required reflective performance.

- If your fleet runs mixed commodities, ensure reflectivity changes don’t conflict with other commodity-specific requirements you may have.

5) Cargo tank inspections/tests: video cameras and fiber optics are allowed (§180.407(a)(7))

HM‑265 adds §180.407(a)(7), authorizing video cameras or fiber optic equipment for any test or inspection (or portion thereof), provided all required areas and elements can be viewed and evaluated.

PHMSA links this change to risk reduction: current practice may require human entry for interior visual inspection, which has risks such as slips/falls and exposure to residual fumes or hazardous materials; the rule allows operators to avoid these risks while maintaining inspection standards.

How to make this audit-proof (and not just “we used a camera”):

- Update the inspection SOP to define what “required areas/elements” means for each inspection type.

- Store inspection outputs in a standardized format (date/time, tank ID, inspector qualification, tool used, areas viewed, findings, and corrective actions).

- Ensure your quality program treats video/fiber optics as an inspection method with defined acceptance criteria, not as an informal workaround.

6) What HM‑265 did not finalize (to prevent confusion with the broader NPRM)

PHMSA states that it is not advancing several other proposals that appeared in the earlier NPRM, including items related to 2017 RSAC recommendations (rail), tank car design/QAP approval delegation, and vessel provisions, among others. PHMSA indicates it may address them in a later final rule. (Related PHMSA rulemaking coverage: Driverless Hazmat Trucking (HM‑266) operational takeaways.)

That matters because many compliance teams have built internal trackers based on the NPRM. HM‑265 is narrower than that earlier package—so close out the items HM‑265 actually finalizes, and keep the rest in a “pending/monitor” bucket.

A Feb. 13, 2026, compliance checklist (fuel fleets, shops, and specialty carriers)

The HM‑265 change is aimed at real operations—multiple loads, tight turns, and fewer chances to stop and swap markings between runs.

Use this as a practical “minimum viable” list for implementation readiness.

If you haul petroleum distillate fuels (gasoline/diesel/kerosene/fuel oil patterns):

- Update the hazmat communications SOP to reflect §172.336’s lowest flash point in the current/previous business day marking option.

- Train dispatch and drivers on the PHMSA definition of business day (operator open and operating in commerce).

- Engineer out the high-risk exception: >10% ethanol blends (UN3475/UN1987) must only be displayed when present during transportation.

- Build “proof on demand” for roadside: a rapid way to show prior business day hauling and current shipping papers.

- Document the conforming rule change in your compliance references: §172.303(b)(4) creates an exception for CTMVs marked under the petroleum distillate marking requirements in §172.336(c).

If you operate a cargo tank facility / CTMV shop:

- Decide whether to use electronic submission for registration statements and establish internal controls around submissions and confirmations (§107.502(d)). For related developments, see compliance coverage.

- Update inspection SOPs and quality documentation if adopting video/fiber optic inspection methods (§180.407(a)(7)).

- If you wrap or coat tanks for reflectivity, align fabrication/finish specs to the revised reflectivity language (§178.337‑1(d)).

If you transport chlorine or service chlorine cargo tanks:

- Align PRD procurement/maintenance records to the incorporated-by-reference Pamphlet 49 requirements, and ensure the shop can demonstrate conformance to the drawings referenced by §173.315(i)(13).

- Recognize the practical effect: the incorporation authorizes the Midland Type A‑14227‑ML PRD design for chlorine service, so documentation should clearly show which approved drawing/design standard applies.

If you manufacture/repair/recondition/test packagings (and do not offer/transport hazmat):

- Re-scope training assignments under §172.704 to reflect the packaging-only exception (not subject to safety training and security awareness training requirements in (a)(3) and (a)(4) when no other HMR functions are performed).

- Update role definitions so the exception does not get applied to employees who actually offer or transport hazardous materials in commerce.

Bottom line for compliance leaders

HM‑265 isn’t just a regulatory tweak—it’s a set of permissions and constraints that will either (a) reduce daily friction and enforcement exposure or (b) create new failure modes if it’s implemented casually. For related reporting on how rules play out in the real world, see TankTransport coverage.

For most fuel fleets, the win is eliminating constant ID swaps by using the lowest flash point in the current/previous business day marking logic—paired with fast, reliable documentation to support it roadside.

The risk is almost entirely concentrated in exceptions and proof: especially >10% ethanol blends (UN3475/UN1987), where HM‑265 is explicit that those IDs may only be displayed when present during transportation, and in the reality that roadside questions will focus on what was hauled in the “previous business day.”

If you implement HM‑265 as a workflow—with clear decision rules, training aligned to real roles, and proof on demand—you achieve the operational benefits PHMSA intended while staying within the rule’s guardrails.

HM-265 Fuel Compliance Wrap-Up: Key Developments

Key Developments

- Effective date and scope: HM‑265 is mandatory as of Feb. 13, 2026 (voluntary compliance allowed as of Jan. 14, 2026) and amends multiple HMR parts affecting fuel transport, cargo tank facilities, and select specialty operations.

- Petroleum distillate ID-number flexibility (headline change): For qualifying petroleum distillate fuels, a cargo tank may display the identification number of the lowest-flash-point fuel transported on the current or previous business day, reducing the need for frequent ID/placard swaps.

- Clear definition for “business day”: A business day is a day the operator is open and operating in commerce, which matters for weekends, holidays, and irregular schedules.

- Ethanol blends >10% carve-out (high-risk exception): For gasoline/alcohol blends with more than 10% ethanol, identification numbers such as UN3475/UN1987 must be displayed as appropriate and may only be displayed when the material is actually present during transportation—a key compliance trap for mixed-load or multi-day operations.

- Conforming “wrong product displayed” fix: HM‑265 adds a targeted exception to the general prohibited-marking rule so that a CTMV using the petroleum distillate marking flexibility under 49 CFR §172.336 isn’t automatically noncompliant under §172.303.

- Enforcement readiness is part of compliance. Because roadside questions often center on what was hauled the previous business day, fleets should have rapid access to supporting information (shipping papers and prior-day load documentation) to defend compliant markings.

- Cargo tank facility registration modernization: Registration statements can be submitted electronically via FMCSA’s portal (paper submission is still allowed), potentially reducing administrative friction for shops and fleets.

- Chlorine PRD standards updated via incorporation by reference: HM‑265 updates the HMR to incorporate Chlorine Institute Pamphlet 49 (Edition 10, 2016), aligning PRD compliance to the drawings in that standard and authorizing additional PRD design options referenced in the incorporated document.

- Packaging-only hazmat employee training reduced: Employees who only perform certain packaging-related functions (and do not offer/transport hazmat) receive expanded training exceptions, including removal of security awareness training for those limited roles.

- Reflectivity flexibility for uninsulated tanks: Compliance can be achieved with external coverings other than paint (e.g., reflective wraps/coatings) so long as reflectivity requirements are met—useful for branding and modernization without falling out of spec.

- Video/fiber-optic inspections are allowed: Cargo tank inspections may use video cameras or fiber-optic devices when required areas cannot be adequately viewed and evaluated, supporting both safety (reduced confined-space exposure) and efficiency.

- Not a “full NPRM” outcome: PHMSA explicitly did not finalize several broader proposals from earlier rulemaking activity, so compliance teams should close out what HM‑265 finalizes and keep other items in a monitor/pending bucket.

Official HM‑265 Sources and Hazmat Compliance References

- Read the final rule as published in the Federal Register at GovInfo: HM‑265 final rule (FR Doc. 2026‑00578).

- Download the rule PDF for offline review at Public Inspection PDF: HM‑265 final rule.

- Track docket materials, comments, and supporting documents at Regulations.gov: Docket PHMSA‑2018‑0080 (HM‑265).

- Use the Federal Register’s reader-friendly page at FederalRegister.gov: “Eliminating Unnecessary Regulatory Burdens on Fuel Transportation”.

- See PHMSA’s document landing page and downloads at PHMSA: Federal Register document 2026‑00578.

- Reference the ID-number marking provision at eCFR: 49 CFR §172.336 (Identification number markings).

- Review the prohibited-marking rule and related exceptions at eCFR: 49 CFR §172.303 (Prohibited marking).

- Confirm cargo tank inspection/test requirements at eCFR: 49 CFR §180.407 (Cargo tank tests and inspections).

- Access the Emergency Response Guidebook used in first-response planning at PHMSA: Emergency Response Guidebook (ERG 2024 PDF).

- Review cargo tank facility registration requirements at eCFR: 49 CFR §107.502 (General cargo tank registration requirements).

- Use FMCSA’s submission guidance and resources at FMCSA: Cargo tank registration and resources.

- Check the training rule text in the eCFR: 49 CFR §172.704 (Hazmat employee training requirements).

- Use PHMSA’s training FAQs and explanations at PHMSA: Hazardous Materials Training Requirements (FAQ).

- For the incorporated chlorine-handling standard, see The Chlorine Institute, Pamphlet 49 (Recommended Practices for Handling Chlorine Bulk Highway Transports).